-

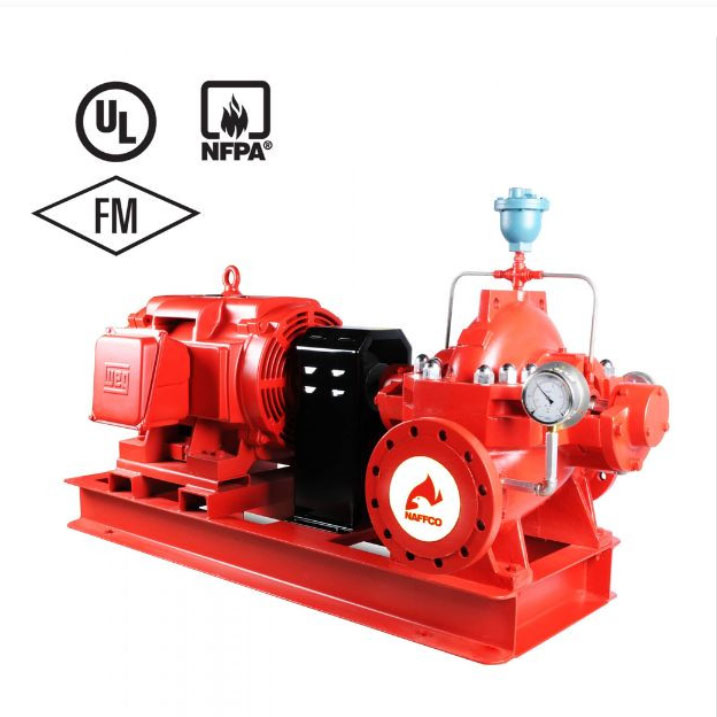

FEATURES Performance characteristics as per NFPA 20 Complete unit responsibility. Complete in-house fabrication capabilities. Hydrostatic testing facilities. Operation run test as per NFPA 20. Horizontal Split case pumps for capacities up to 8000 USGPM. Drivers: Electric motor drive or diesel engine drive. Electrical testing capabilities for motors and controllers connected to fire pumps as per NFPA standards. Capable to supply additional accessories wherever required

FEATURES Performance characteristics as per NFPA 20 Complete unit responsibility. Complete in-house fabrication capabilities. Hydrostatic testing facilities. Operation run test as per NFPA 20. Horizontal Split case pumps for capacities up to 8000 USGPM. Drivers: Electric motor drive or diesel engine drive. Electrical testing capabilities for motors and controllers connected to fire pumps as per NFPA standards. Capable to supply additional accessories wherever required -

FEATURES

- Performance characteristics as per NFPA 20

- Complete unit responsibility.

- Complete in-house fabrication capabilities.

- Hydrostatic testing facilities.

- Operation run test as per NFPA 20.

- Horizontal End Suction pumps for capacities up to 750 USGPM

- Drivers: Electric motor drive or diesel engine drive.

- Electrical testing capabilities for motors and controllers connected to fire pumps as per NFPA standards.

- Capable of supplying additional accessories wherever required.

-

FEATURES

- Performance characteristics as per NFPA 20

- Complete unit responsibility.

- Complete in-house fabrication capabilities.

- Hydrostatic testing facilities.

- Operation run test as per NFPA 20.

- Vertical Turbine models pumps for capacities up to 6000 USGPM.

- Drivers: Electric motor drive or diesel engine drive.

- Electrical testing capabilities for motors and controllers connected to fire pumps as per NFPA standards.

- Capable of supplying additional accessories wherever required.

-

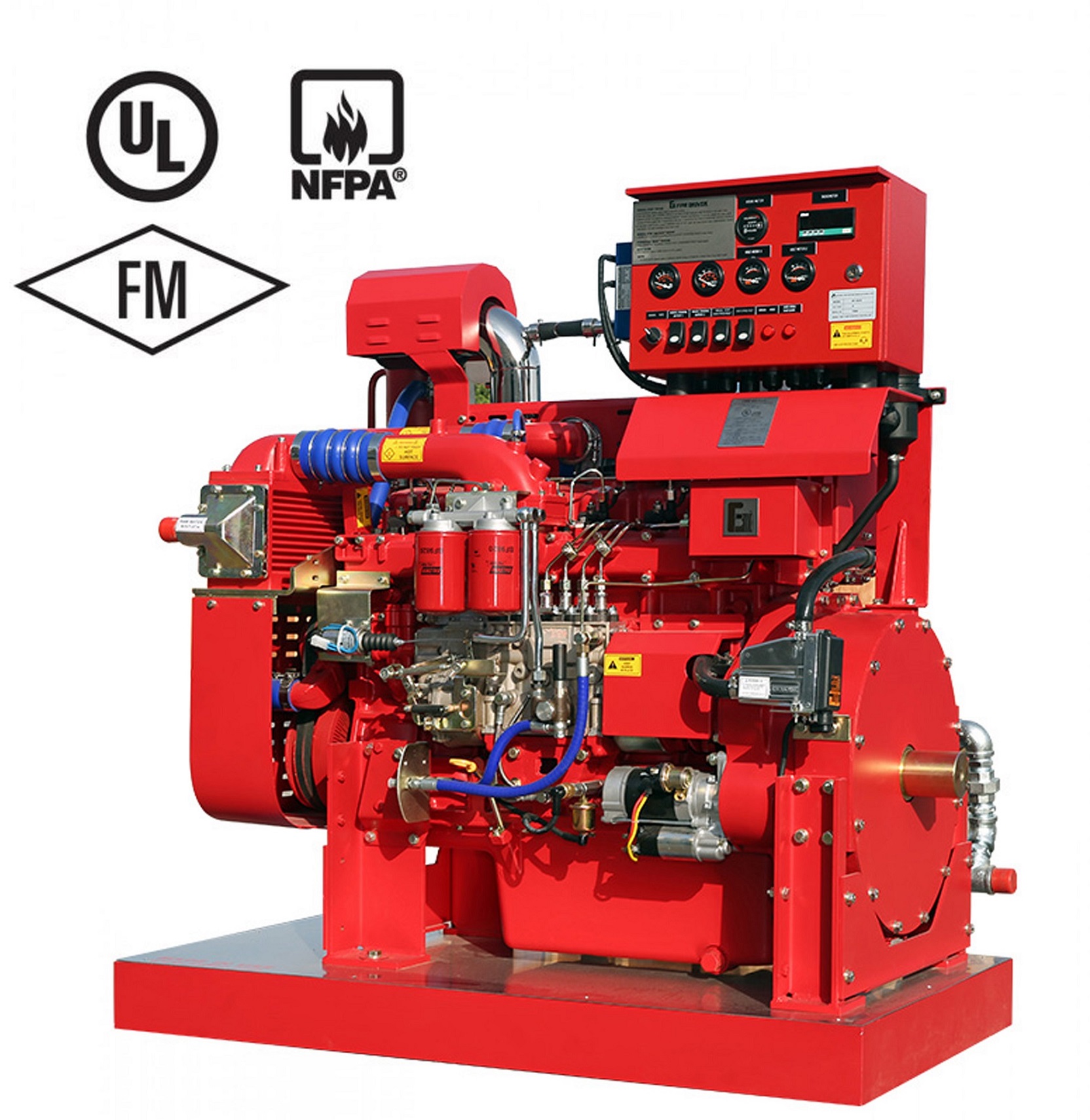

SPECIFICATION DIESEL ENGINE RANGES (SERIES: FD - R / FD - H / FD - HN / FD – HT / FD-Hi)

SPECIFICATION DIESEL ENGINE RANGES (SERIES: FD - R / FD - H / FD - HN / FD – HT / FD-Hi)

* These values only indicate the overall range available in this series. For the availability of any specific ratings and details of its certification, please contact the factory.Rated Output 10 HP - 500 HP Rated Voltage 380-400-415v (50Hz), 208-230v* (60Hz), 380-400v (60Hz), 440-460v (60Hz) & 575 (60Hz) Rated Speed 2923 - 2980 (50Hz) & 3506 - 3575 (60Hz) -

RATINGS SERIES: NM, TEFC ENCLOSURE 2 POLE

RATINGS SERIES: NM, TEFC ENCLOSURE 2 POLE

*Motors rated at this voltage are available only for power ratings from 15 to 100 Hp. 4 POLERated Output 10 HP - 500 HP Rated Voltage 380-400-415v (50Hz), 208-230v* (60Hz), 380-400v (60Hz), 440-460v (60Hz) & 575 (60Hz) Rated Speed 2923 - 2980 (50Hz) & 3506 - 3575 (60Hz)

** Motors rated at this voltage are available only for power ratings from 15 to 100 Hp.Rated Output 10 HP - 400 HP Rated Voltage 380-415v (50Hz), 208-230v* (60Hz), 380-400v (60Hz), 460v (60Hz) & 575v (60Hz) Rated Speed 1460-1480 RPM (50Hz) & 1750 -1780 RPM (60Hz) -

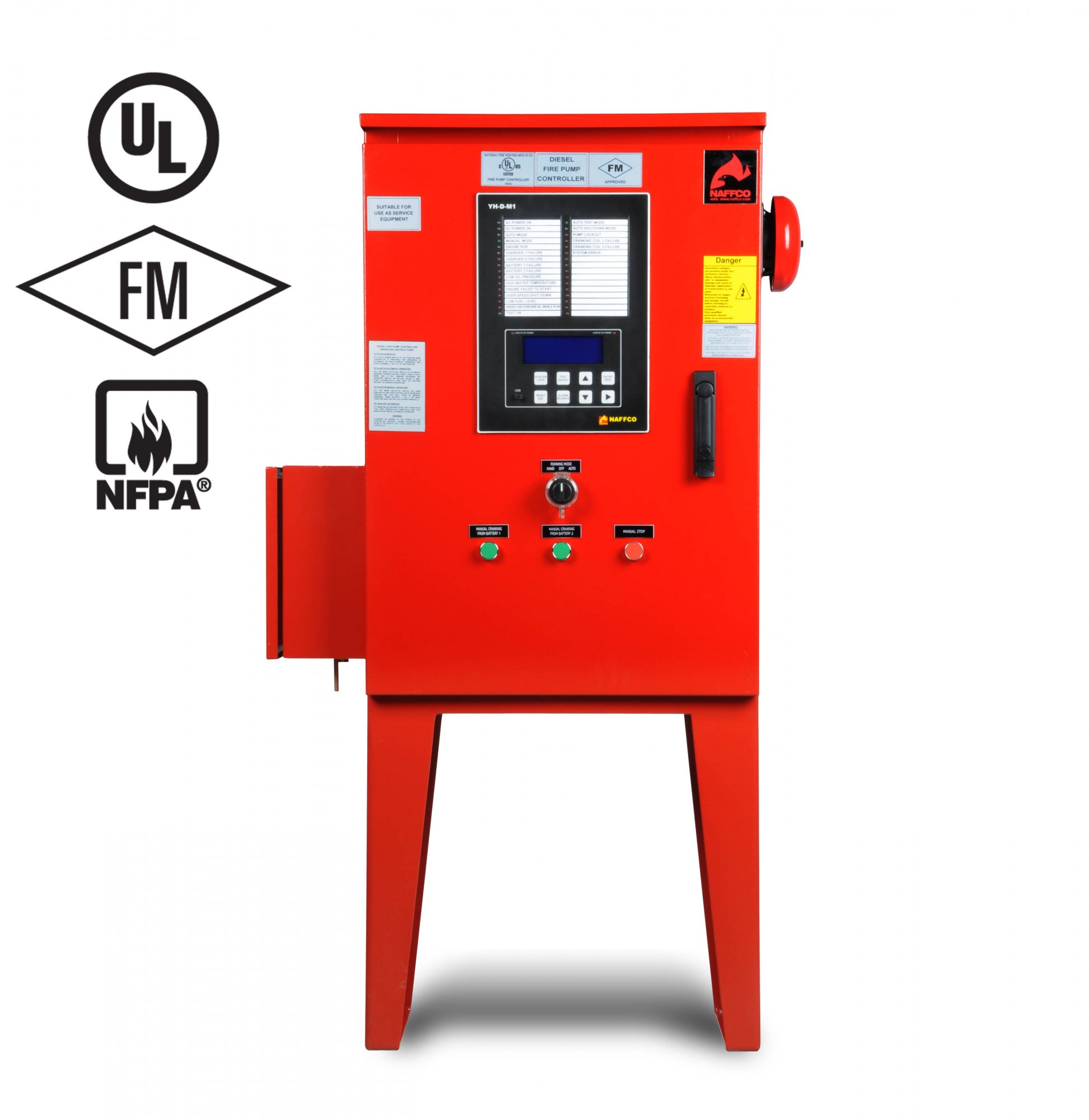

SPECIFICATION

DC Voltage(VDC) Line Voltage(VAC) Enclosure Size(mm) 12 220/110 900 (H) x 600 (W) x 300 (D) 24 220/110 900 (H) x 600 (W) x 300 (D) -

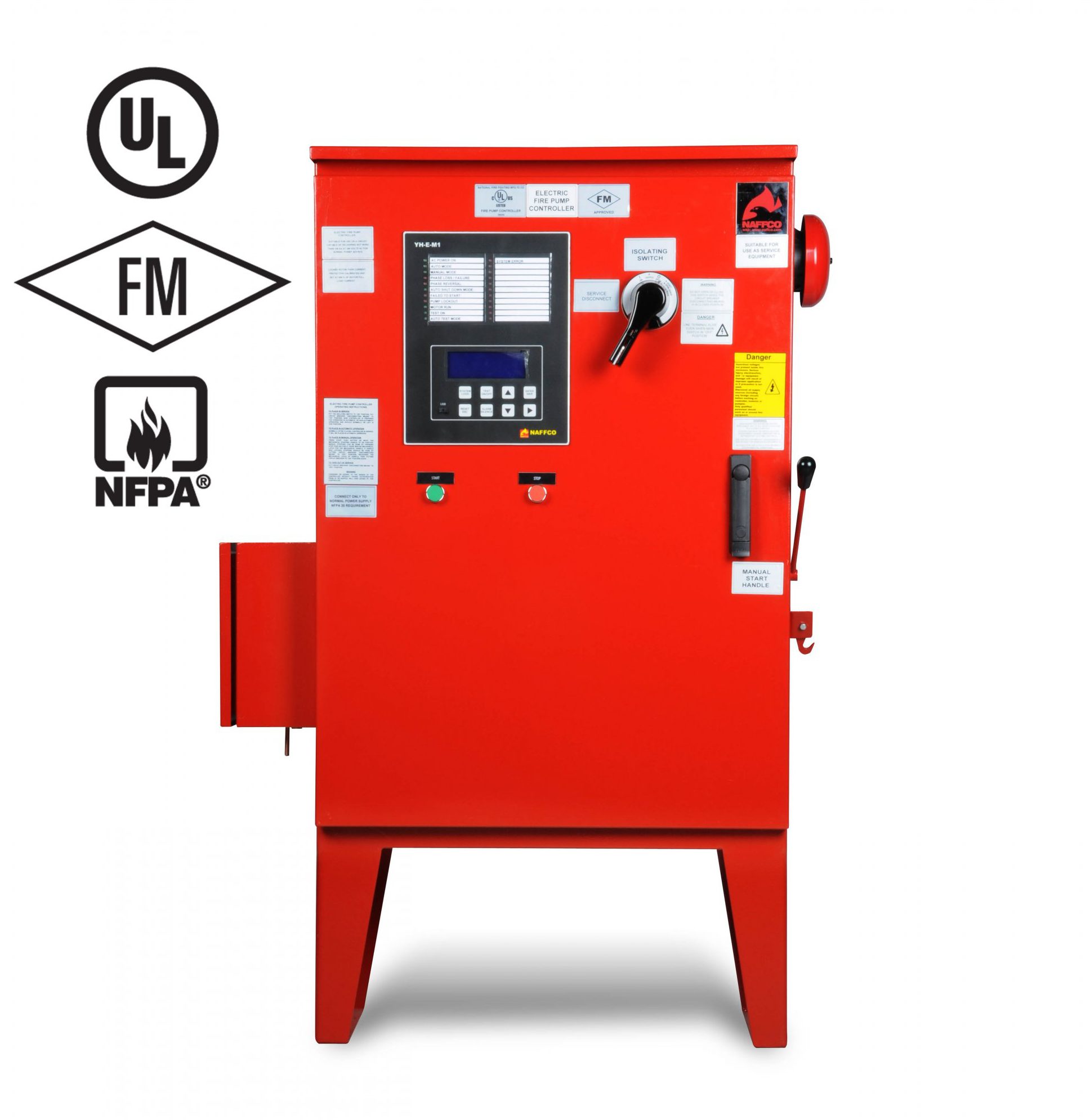

SPECIFICATION

MODEL - STARTING TYPE

- NFY-DOM1 - Direct On Line

Motor Power (HP0 Rated Voltage (V) Frequency (Hz) Rated Circuit(A) Short Circuit(kA) 15 380 - 415 50 / 60 27 100 20 380 - 415 50 / 60 34 100 25 380 - 415 50 / 60 44 100 30 380 - 415 50 / 60 51 100 40 380 - 415 50 / 60 66 100 50 380 - 415 50 / 60 83 100 50 380 - 415 50 / 60 103 100 75 380 - 415 50 / 60 128 100 100 380 - 415 50 / 60 165 100 -

RATINGS

RATINGS

FEATURES ENCLOSURE OPTIONS: NEMA 2, NEMA 3, NEMA 4, NEMA 4x, NEMA 12 STANDARD FEATURESPower Rating 1.5 - 7.5 HP DOL Starter & 10 - 40 HP Star Delta Starter Voltage 230/380/415/480 V Frequency 50/60 hz - Main disconnect switch with rotary handle, sized for disconnecting motor horsepower and voltage.

- Motor Starter (DOL) or Overload Relay (Star-Delta) rated to the motor's horsepower, with thermal and short circuit protection.

- Rated motor connectors.

- Circuit breaker for protection of control circuit and motor.

- Star—Delta starting timer. (in Model NFY-JSD1 & NFYJSD1-M1)

- Power ON/Healthy indicator/free contact.

- Pump Run indicator/free contact.

- Pump Trip indicator/free contact.

- Adjustable pressure switch.

- Run Period Timer

- Touch control panel to operate, monitor, and set up the controller.

- Automatic and manual selection on the touch panel screen.

- Real-time voltage and pressure reading on screen.

- Real-time pump running status, alarm details, and time delay on screen.

- Password protection.

- Screen saver mode.

- Up to 4 auxiliary inputs and 3 output ports.

- Up to 5 predefined options to select on input auxiliary.

- Up to 24 predefined options to select on output auxiliary

-

FUEL TANK CAPACITY

Type Cylindrical, Horizontal Fuel Tank Size 70 - 750 US Gallons 1000 - 2000 US Gallons * * * * With Pad Plate & ladder

FEATURES

- Meets NFPA 30 requirements.

- Sized as specified by NFPA 20 for fire pump applications.

- Designed and Fabricated in accordance with UL 142 (Steel Aboveground Tanks for Flammable and Combustible Liquids) standard.

- Tested for tightness against leakage.

- Top quality fittings and fabrication materials.

- Sturdy lifting lug and legs.

- Vent opening to prevent build-up of pressure or vacuum inside the tank during filling, emptying or due to atmospheric temperature changes.

- Approved welding process.