- Uncomplicated system design eliminates design and installation errors.

- Installation time significantly reduced.

- Innovative design eliminates conduit and corner pulleys.

- Advanced detection system installs quickly and easily.

- Color-coded nozzles for easy identification.

- Flexible piping requirements allow for unlimited system configurations.

- Best coverage in industry.

- Online & face to face training.

-

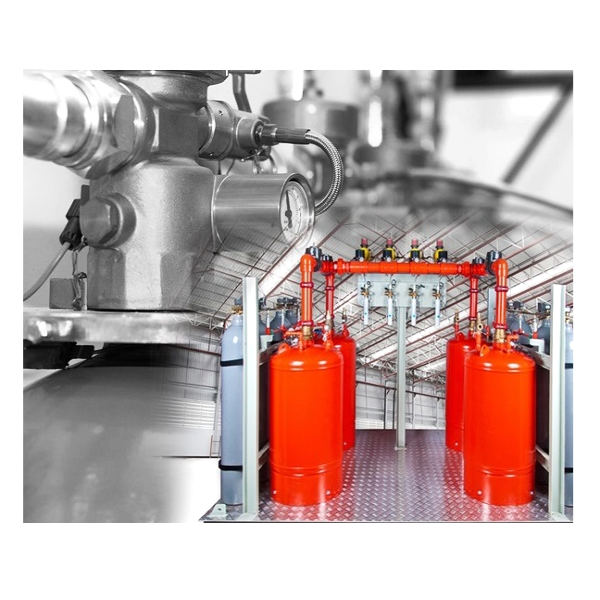

SYSTEM CYLINDERS The models NF-KS5, NF-KS10, NF-KS15 and NFKS20 cylinders are designated by flow point capacity (so the NF-KS5 supports five (5) flow points) instead of the amount of agent they hold. Recharge is available in 5 and 10 flow point containers so there’s never a chance of error. DISCHARGE NOZZLES All five (5) Kitchen Mister nozzles come equipped with a color identification band, red, blue, green, white and yellow. This allows for easy identification of the nozzle even when it’s installed in difficult locations such as a duct or plenum area. The nozzle is also stamped with its model number. DEALER FRIENDLY FEATURES

SYSTEM CYLINDERS The models NF-KS5, NF-KS10, NF-KS15 and NFKS20 cylinders are designated by flow point capacity (so the NF-KS5 supports five (5) flow points) instead of the amount of agent they hold. Recharge is available in 5 and 10 flow point containers so there’s never a chance of error. DISCHARGE NOZZLES All five (5) Kitchen Mister nozzles come equipped with a color identification band, red, blue, green, white and yellow. This allows for easy identification of the nozzle even when it’s installed in difficult locations such as a duct or plenum area. The nozzle is also stamped with its model number. DEALER FRIENDLY FEATURES -

NAFFCO fire suppression system is capable of providing local application hazard protection for mobile equipment and industrial Hazards. In certain industrial hazards, total flooding can be used.

Apart From this, we also supply powder based Fire Extinguishers.

The basic system consists of: Dry Chemical Agent Storage Tank(s), Expellant Gas cartridge, Distribution Hose and Nozzles, Manual/ Automatic Actuator, Automatic Detection System, and Accessories.

SEE THE ATTACHED CATALOG

-

TECHNICAL INFORMATION

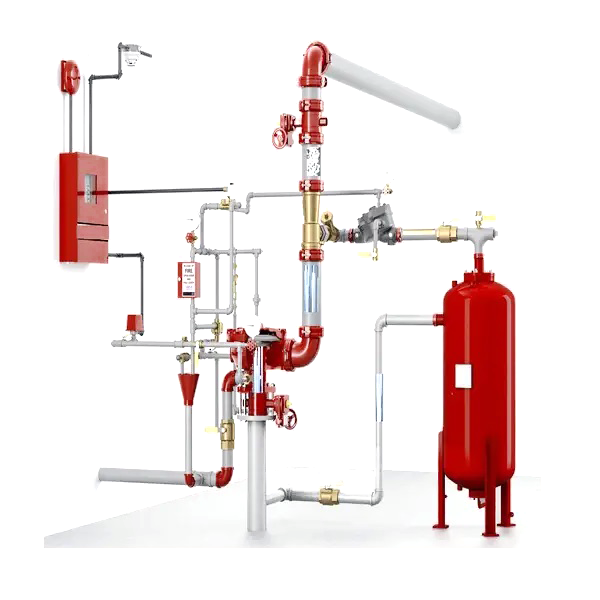

Tank Shell Carbon Steel, SA 516 Gr.70. Bladder Vinyl Based Polymer Pressure Relief Valve (Optional) Brass Construction with Set Pressure @ 15 bar Internal Piping Perforated PVC, sch. 80, Flanges ASTM A105, Class 150 Water Pipe Carbon Steel. sch. 40. Foam Pipes Stainless Steel. sch. 40. Vent/Drain/NRV Valves Brass/Bronze. Sight Glass Valve Sight Gauge with Shut Off & Drain Valve Painting External Zinc Rich Primer with Red Enamel Finish Painting Internal Zinc Rich Primer with Coal Tar Epoxy Paint DESIGN DATA

Tank mounting Vertical Concentrate Storage Capacity 50-1200 Gallon (see tables) Flow Range 78 - 9500 LPM Foam Concentrate AFFF 3%,6% Design Pressure 175PSI (12.09 bar) Test Pressure 227PSI (15.69 bar) Ratio Controller Size 2½”,3", 4” & 6” Storage Temperature +2°C - +49°C Foam Concentrate Proportioning Orifice 3%, 6% *NOTE: The UL listing does not include proportioning of 6% Foam Concentrate and 2½" Ratio Controller

RATIO CONTROLLER DETAILS

SIZE INLET / OUTLET FLANGE LENGTH (mm) ORIFICE DIA. (mm) 3% 6% 65NB ANSI CLASS 150 190 6.9 9.5 80NB 266 10.7 15.04 100NB 332 15.7 21 150NB 342 28.7 44.5 RATIO CONTROLLER SIZE & FLOW RATE

SIZE FLOW RATE , 3% (as per UL) FLOW RATE , 3% (as per FM) FLOW RATE, 6% (as per FM) 65NB 100 - 1550 LPM 78 - 1036 LPM 159 - 984 LPM 80NB 260 - 3000 LPM 270 - 3000 LPM 270 - 3000 LPM 100NB 650 - 6000 LPM 660 - 5750 LPM 633 - 3922 LPM 150NB 1200 - 12000 LPM 1090 - 9530 LPM 674 - 4012 LPM